g

+ g spool

1.75 mm

±

µm

%

Made in

Made inCZ

oC

oC

What the graph above means?

We measure the diameter of the filament on the X and Y axis more than 4700× per second during the whole manufacturing process. You can see averaged data of these measurements in the graph, so you can make sure that your filament spool is well made and is within the manufacturing tolerance of ±0.02 mm (±0.03 mm for blended materials, PETG Tungsten; ±0.04 mm for PCCF, PA11CF).

Prusament ASA details

Characteristics

ASA is a strong and versatile material. A higher melting point than PLA gives ASA excellent heat resistance, your prints will not show signs of deformation up to 93 °C. Unfortunately, ASA has a very high thermal expansion compared to PLA, which complicates printing, especially for larger models. Even with a heated bed set to 110 °C, the print can begin to warp and peel off the bed. The material also produces odor during printing.

Tips

High temperature resistance, one of the advantages of ASA, brings a certain side-effect that needs to be taken into account during printing: printed objects are prone to warping and lifting from the print bed. This is caused by the temperature difference between the nozzle (265 °C) and the ambient room temperature. If the print cools down unevenly, it creates an internal tension, which results in print issues. Generally speaking, 10×10cm objects should print fine, however, there are many factors entering the equation – shape, infill, ambient temperature, airflow and others.

ASA printing requires specific conditions for successful results. It’s important to run the prints in a well-ventilated room, because the material releases fumes and substances that could pose a potential health risk. However, when ventilating the room, do not create a draft around the print – this will negatively impact the result.

Usage

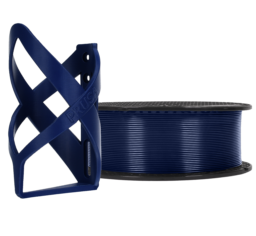

One of the biggest pros of ASA is its UV stability and the possibility to use acetone for processing – namely for smoothing out the surface or for gluing multiple ASA parts together. High temperature resistance is also a plus. For example, we use ASA to print the fan-shroud part for our 3D printers – this part creates an optimal airflow for cooling down the printed object.