Prusament ASA

ASA can be considered a true successor to ABS. Compared to ABS, it’s UV stable, it doesn’t suffer from shrinking so badly, and the fumes produced are much less noticeable.

- Can be smoothed

- High temperature resistance

- Recyclable

- Tough

- UV stable

- All details

Characteristics

Pros

- Great for outside use - UV stable

- High temperature resistance

- Detailed prints without a stringing effect

- Can be smoothed with acetone vapors

- Can be easily sanded / post-processed

- Great layer adhesion

- Soluble in acetone - can be used for gluing

- High impact and wear resistance

- Tough

- Recyclable

Cons

- Large models have a tendency to warp

- Produces odors during printing (less than ABS)

- Contains styrene

- Requires high printing temperatures

- Hygroscopic

Application

High temperature resistant parts

Thanks to the high-temperature resistance up to 93 °C, ASA is a great choice for heat-stressed parts. Also, fan-shroud on Original Prusa i3 MK3S is newly made of ASA material.

Smoothed surface

ASA can find its place on projects, where you need smooth surface similar to a surface treated with car paint. However, this also leads to a loss of small details and rounding of sharp edges.

Outdoor use

Thanks to UV stability, ASA is an ideal choice for outdoor use. The material will keep toughness and durability for a long time and will not turn yellow.

Details

- Printing difficulty

- Medium

- Temperature resistance

- 93 °C

- Toughness

- High

- Susceptibility to warping

- High

- Odor

- Yes

- Post processing

- Easy

- Simple to sand (both wet and dry)

- Solubility

- Yes

- Acetone

- Elasticity

- Medium

- Print speed

- Fast

- Details

- 0.10 mm and more

- Abrasivity

- None

- Hard to break

- Yes

ASA can be considered a true successor to ABS. Compared to ABS, it’s UV stable, it doesn’t suffer from shrinking so badly, and the fumes produced are much less noticeable. ASA 3D prints are durable, tough and suitable for a wide range of applications. The solidification temperature is also higher compared to PLA and PETG, which gives objects printed from ASA an excellent temperature resistance – there are no signs of deformation up to temperatures near 93 °C. Thanks to all these properties, ASA is especially suitable to print objects meant for long-time outside use.

However, you can still encounter some issues related to shrinking (warping) of the material – especially when printing larger models. Even with the heatbed set to 110°C, the prints can shrink and warp, causing them to detach from the print bed. However, the effects are much less severe compared to ABS. This issue can be eliminated by printing inside an enclosure or by adding a tall skirt around the object.

Download Safety Data Sheet (PDF)

Printer requirements

| Bed | Temperature: 110 ± 5 °C Heated Bed Recommended Skirt or Enclosure Recommended |

|---|---|

| Print Surface | PEI sheet Glass plate |

| Extruder | Temperature: 260 ± 5 °C No special hot-end required |

| Cooling | Part Cooling Fan Required Fan Speed: 30% |

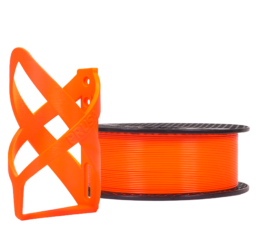

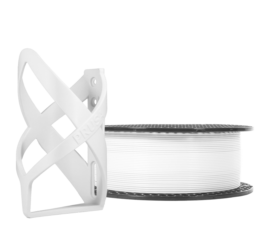

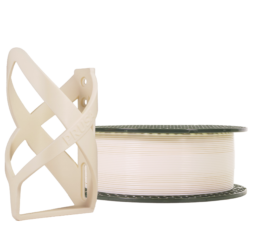

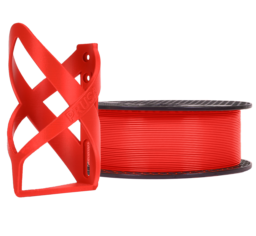

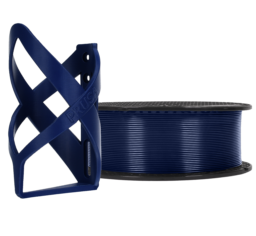

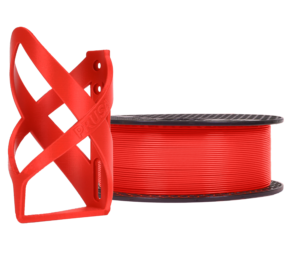

Available colors

Beginners tips & tricks

Print bed preparation

For ASA printing, we recommend using the satin spring steel sheet. With the powder-coated or smooth sheet, the adhesion of the material can be too strong, which could potentially result in damage to the surface of the sheet. The textured and PEI smooth spring sheet preparation are easy: simply clean the surface with isopropyl alcohol and apply glue. To remove the print, wait until it cools down – it will then pop off easily.

Post-processing

ASA is a material that can be easily post-processed. It’s possible to sand the parts using wet or dry sanding methods, smooth them out with acetone vapors, and glue them together with acetone. The result of acetone post-processing will be a very glossy, smooth surface similar to a surface treated with car paint. However, this also leads to a loss of small details and rounding of sharp edges.