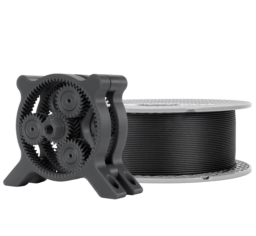

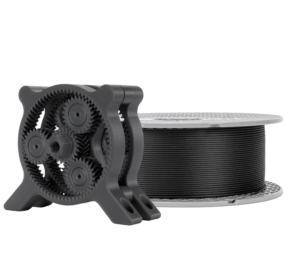

Prusament PA11 (Nylon) Carbon Fiber

Prusament PA11 Nylon Carbon Fiber is a technical filament with excellent heat, chemical and mechanical resistance. The material is filled with carbon fibers to improve its dimensional stability. In most parameters, it’s better than Prusament PC Blend Carbon Fiber. It’s suitable for making prototypes in the automotive industry, aerospace, hobby, etc.

Characteristics

Pros

- High-temperature resistance (up to 190 °C)

- Great chemical resistance

- Low coefficient of friction

- Abrasion resistant

- Very slow humidity absorption - compared to other types of PA

- Great-looking matt surface

- Very low shrinkage during the print

Cons

- Special print sheet (or separation layer) required

- Hardened steel nozzle required

- Lower layer-to-layer adhesion (compared to pure PA)

- Occasional filament drying required

- A higher price (compared to other Prusaments)

- Significant odor

Application

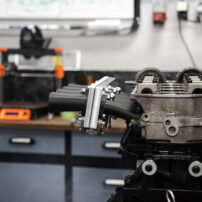

High temperature resistant parts

Thanks to the high-temperature resistance up to 190 °C Prusament PA11 Nylon Carbon Fiber is a great choice for heat-stressed parts for professional use.

Mechanically stressed parts

Because of its toughness and durability, the Prusament PA11 Nylon Carbon Fiber is optimal for mechanically stressed parts.

Details

- Printing difficulty

- Easy

- Toughness

- Medium

- Odor

- High

- Solubility

- No

- Print speed

- Fast

- Abrasivity

- High

- Temperature resistance

- 190 °C

- Susceptibility to warping

- Low

- Post-processing

- Easy (easy dry and wet sanding)

- Elasticity

- Low

- Hard to break

- Yes

- Hard to break the filament

- No

Among the Prusament filaments, Prusament PA11 Nylon Carbon Fiber has by far the best temperature and chemical resistance. Printed parts withstand up to 190 °C (depending on stress) and have increased resistance to many solvents (NaOH, Methanol, Ethanol, Toluene, Acetone, motor oils, benzene, diesel, etc.).

Polyamide PA11 is a material made from castor oil, the carbon fibers used for this material are recycled, the same as for the Prusament PC Blend Carbon Fiber.

The best use of the Prusament PA11 Nylon Carbon Fiber is for making special chemically, mechanically and heat-stressed parts, such as car engine components.

We recommend using our PA Nylon steel sheet for printing polyamides, including Prusament PA11 Carbon Fiber. The necessity of using a special sheet (or separation layer) and a hardened steel nozzle makes this material suitable for advanced users.

Download Safety Data Sheet (PDF)

Printer requirements

| Bed | Temperature: 110 ± 10 °C Heated Bed is necessary Enclosure recommended |

|---|---|

| Print Surface | special PA Nylon spring sheet treated with clean water |

| Extruder | Temperature: 285 ± 10 °C A hardened steel nozzle is needed |

| Cooling | Not recommended |

Available colors

Beginners tips & tricks

Print surface preparation

The best adhesion is provided by our special PA Nylon steel sheet. This sheet should be cleaned only with water. If cleaned with IPA (and other alcohol-based solvents), the lifespan of the sheet decreases rapidly and the risk of damaging the sheet increases too. We don’t recommend any other surface preparations. If you need to clean visible grease stains (fingerprints), use water with a dish cleaning solution.

Printing on standard PEI print sheets is possible but comes with limitations. It’s necessary to spread paper glue (glue stick) on the surface and choose a proper 3D model. Large prints will tend to warp, small prints won’t stick to the print surface.

Printing in enclosure

Printing polyamides release a strong odor with potentially hazardous particles. We recommend printing in an enclosure placed in a well-ventilated room. This way you’ll get better mechanical properties, reduced warping of large parts and reduced emitting of any hazardous particles. If the room is closed, just don’t forget to open the windows and ventilate it properly after finishing the print.