g

+ g spool

1.75 mm

±

µm

%

Made in

Made inCZ

oC

oC

What the graph above means?

We measure the diameter of the filament on the X and Y axis more than 4700× per second during the whole manufacturing process. You can see averaged data of these measurements in the graph, so you can make sure that your filament spool is well made and is within the manufacturing tolerance of ±0.02 mm (±0.03 mm for blended materials, PETG Tungsten; ±0.04 mm for PCCF, PA11CF).

Prusament PA11 (Nylon) Carbon Fiber details

Characteristics

Polyamide PA11 is a material made from castor oil, the carbon fibers added to this filament are recycled, as with Prusament PC Blend Carbon Fiber. Probably the biggest advantage of this material is its high-temperature resistance, up to 190 °C depending on the load. This makes it perfectly suitable for printing special parts, such as parts of machines that emit heat (motors, etc.).

The second major advantage of PA11 (and polyamides in general) is its excellent chemical resistance to a range of solvents. PA11 has good resistance to bases (e.g. NaOH), alcohols (Methanol, Ethanol), toluene, acetone, motor oil, petrol, diesel, etc.

The PA11 we use is a type of polyamide used primarily for SLS technology. This is a rather unexplored area in the field of FFF 3D printing. We have experimented quite a lot in this field and finally achieved more than a good result. Why did we choose PA11? Commonly used PA6 and PA12 polyamides have a number of disadvantages: PA6 is extremely hygroscopic, making it extremely difficult to print with it even 1 day after unpacking. In some cases, PA6 can get absorb too much moisture even during long printing runs. PA12 isn’t as hygroscopic, but it warps extremely and has very poor adhesion to a standard PEI print sheet. PA11 is a good middle ground – it’s less hygroscopic and offers better adhesion to the PEI print sheet (for small and medium-sized models).

Thanks to added carbon fiber, Prusament PA11 Carbon Fiber is virtually non-warping. Compared to pure polyamide, it has slightly weaker interlayer adhesion, roughly comparable to our Prusament PC Blend Carbon Fiber – still a very good result.

Tips

Together with Prusament PA11 Carbon Fiber Black, we are also releasing a brand new printing sheet designed specifically for printing polyamides. The reason for this is the low adhesion of PA11 to our classic PEI printing sheets. Up until now, we have recommended printing polyamides on textured or satin print sheets with a layer of adhesive (glue stick), but this has not proven to be a very suitable option. Sure, smaller models with sparse infill can be printed on PEI sheets coated with stick glue but for reliable printing of technical models, you need something better. Prusament PA11 Carbon Fiber in particular can easily peel and warp when printed on conventional sheets, despite being filled with carbon fiber. That’s why we have developed a new surface layer of a special material that provides significantly better adhesion for polyamide printing materials.

In addition to a special print sheet, printing with a hardened nozzle is required due to the highly abrasive properties of carbon fiber.

We recommend printing on a printer in an enclosure or placing the printer in a well-ventilated room (see our material safety datasheet). Printing polyamide releases a relatively strong odor into the air and emits potentially hazardous particles (UFP – ultrafine particles). Our Original Prusa Enclosure is an ideal option. Not only will the odor be reduced, but the higher ambient temperature will improve the adhesion between printed layers. Once you finish printing in the enclosure, open the window first and then open the doors of the enclosure to quickly change the air.

Usage

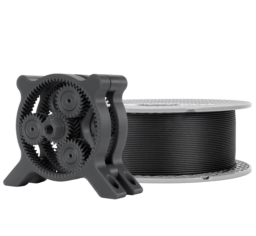

Prusament PA11 Carbon Fiber Black, is a material perfectly suited for use in the automotive industry, but also great for printing durable mechanical parts at home – components for drones and other RC models, gears and other technical parts.