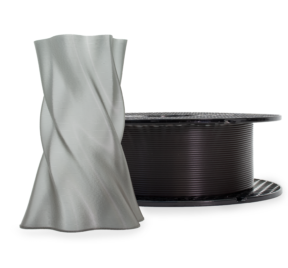

Prusament PVB

PVB is a special material suitable for printing lamp shades, vases, jewellery and other design parts. Its main advantage is the solubility in isopropyl alcohol (IPA) that allows to produce models with glass-like surface. Thanks to its low warping, PVB is suitable for printing large models.

- Can be smoothed

- Easy to print

- Low warping

- Transparent

- All details

Characteristics

Pros

- Print settings similar to PLA

- Filament transparency

- Suitable for design parts, vases, lamps etc.

- Chemical smoothing with IPA

- Great surface adhesion

- Good tenacity (similar to CPE)

- Good tensile strength (similar to PETG)

- Low warping (lower than PLA)

- Possibility of using 0.8mm nozzle

Cons

- Poor layer to layer adhesion (slightly worse than PLA)

- Low temperature resistance

- Hygroscopic filament (absorbs moisture)

- Higher price

Application

Vases

Easy IPA smoothing makes PVB great for printing glass-like vases and other unconventional household items.

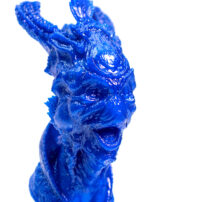

Jewellery

Thanks to low melting temperature, it’s possible to print detailed parts. This can be used for printing jewellery and other fashion items.

Details

- Printing difficulty

- Easy

- Toughness

- High

- Odor

- No odor

- Solubility

- Yes (IPA)

- Print speed

- Fast

- Abrasivity

- None

- Temperature resistance

- Under 60 °C

- Susceptibility to warping

- None

- Post processing

- Difficult (wet sanding)

- Elasticity

- None

- Details

- Under 0.2 mm

- Hard to break

- no

Polyvinyl butyral (PVB) has similar mechanical properties as PETG, print settings are almost identical to PLA. Thanks to its translucency and easy smoothing with IPA it’s great for printing visual models such as unconventional vases, jewellery, lamp shades and other design parts.

The most ideal parts are those, which require filament translucency. It’s good to tweak print settings, especially layer height, number of perimeters and infill density. We recommend printing with a large nozzle diameter in combination with spiral vase mode.

PVB weakness is low heat resistance which is similar to PLA (60 °C).

Download Safety Data Sheet (PDF)

Printer requirements

| Bed | Temperature: 65–85 °C Heated Bed required Enclosure not required |

|---|---|

| Print Surface | Smooth PEI or satin print sheet |

| Extruder | Temperature: 215 ± 10 °C No special hot-end required |

| Cooling | Part Cooling Fan Required Fan Speed: 100% |

Available colors

Beginners tips & tricks

Print surface preparation

To achieve the best adhesion of the print surface, it is important to keep it clean. Cleaning the surface is simple: the best option is Isopropyl alcohol (available in drugstores) which works best not just for PVB, but other materials as well.

Pour a small amount of IPA on an unscented paper towel and wipe the print surface. The bed should be cleaned when it’s cold for the best results but it can also be cleaned when already preheated for PVB, just be careful not to touch the bed surface or the nozzle. Keep in mind that when cleaning at higher temperatures, the alcohol will evaporate before it can clean anything. Alternatively, you can clean the bed with warm water and a few drops of dish soap on a paper towel. Denatured alcohol is also another option.

Chemical smoothing

It’s possible to smooth the surface of the print and glue PVB models together using IPA. The result of IPA post-processing will be a very glossy, glass-like smooth surface. However, this also leads to a loss of small details and rounding of sharp edges.

Detailed smoothing description can be found in our dedicated article, general smoothing instructions can be found in our older article.

Number of perimeters and transparency

You can take advantage of PVB transparency to produce unusual-looking models, especially in combination with underlight and chemical smoothing. It’s good to print models in a spiral vase mode, then smooth them out with IPA and achieve glass-like transparency. Higher number of perimeters can influence the light permeability: The more perimeters you print, the less light will go through.

Keep the filament dry

PBV is very prone to absorbing moisture. Always put the spool back inside the bag with silica gel or let it dry for 4 hours at 60 °C before printing!