Prusament PETG

PETG is one of the most commonly used filaments. It is an excellent choice for printing mechanically stressed parts. Compared to PLA, it is more heat resistant, more flexible and less brittle.

- Durable & Tough

- Easy to print

- Low warping

- Strength & Rigid

- Temperature resistant

- All details

Characteristics

Pros

- High temperature resistance

- Easy to print

- Low shrinking and warping

- Strength and Durability

- Not brittle

- Simple to sand

- Mostly odorless while printing

- Glossy and smooth surface finish

- Strong layer to layer adhesion

- Low water absorption

- Recyclable

Cons

- Not suitable for tiny parts

- Possibility of stringing

- Poor bridging characteristics

- Strong adhesion to the bed - be careful when you’re removing the print

- Cannot be acetone smoothed like ABS

- Supports are harder to remove

- Prone to scratches (more than PLA)

Application

Mechanical parts

Thanks to strength and durability, PETG is a great choice for mechanical parts. Also plastic parts on Original Prusa i3 MK3 are made of PETG material.

Details

- Printing difficulty

- Easy to medium

- Temperature resistance

- 68 °C

- Toughness

- High

- Susceptibility to warping

- Low

- Odor

- No odor

- Post processing

- Average

- Simple to sand (wet and dry)

- Solubility

- No

- Elasticity

- Low

- Print speed

- Fast

- Details

- 0.15 mm and more

- Abrasivity

- None

- Hard to break

- Yes

PETG is a very tough material with good thermal resistance. Its use is universal but especially suitable for mechanical parts and both indoor and outdoor use. PETG has almost no warping, so printing large objects isn’t a problem. We use PETG to print parts for our printers!

PETG is one of our favorite materials for 3D printing. It’s almost as easy to print as PLA, but it can offer many mechanical properties that PLA prints just cannot achieve.

The G in the acronym PETG stands for Glycol which is added during the manufacturing process. Glycol modifies the properties of PET, so that it’s easier to print, less brittle and clearer when printing with semi-transparent variants. PETG has a low thermal expansion, so even when printing big objects, and without an enclosure, it rarely lifts from the bed and warps. In addition to that, PETG is ductile. It has a healthy amount of flex which can prevent parts from breaking under pressure.

Unlike PLA or ABS, PETG tends to ooze a bit and may leave strings of plastic on your print. You can fight this with increasing retraction and playing with hotend temperature, but if you use our filament presets in PrusaSlicer or PrusaControl, we already did that for you and the amount of stringing is minimal. If you witness a tiny bit of stringing anyway, you can get rid of it by quickly blasting your finished prints with a heat gun.

If you can handle the oozing and strong adhesion, you’ll be left with a very durable print, that is considerably temperature resistant and usable for both indoor and outdoor use.

Download Safety Data Sheet (PDF)

Printer requirements

| Bed | Temperature: 80 ± 10 °C Heated Bed Recommended Enclosure not required |

|---|---|

| Print Surface | PEI Glass plate Painter’s tape Glue stick |

| Extruder | Temperature: 250 ± 10 °C No special hot-end required |

| Cooling | Part Cooling Fan Required Fan Speed: 50% |

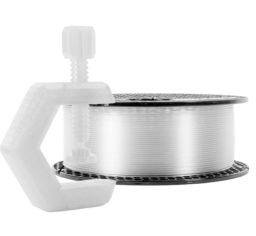

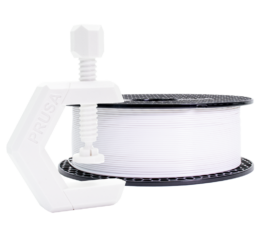

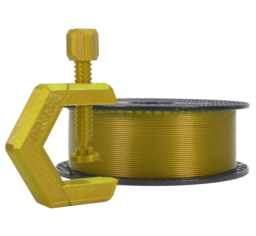

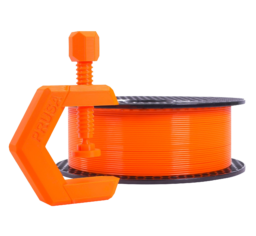

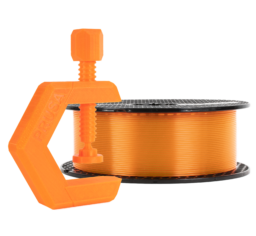

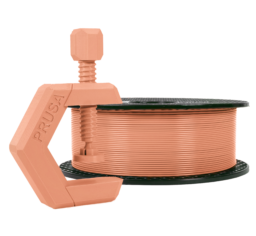

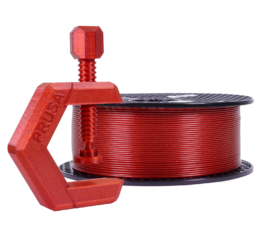

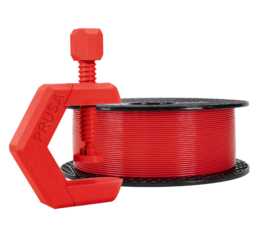

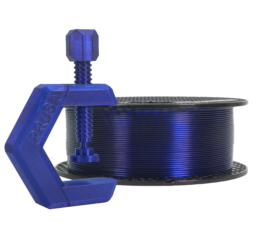

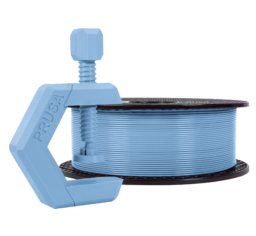

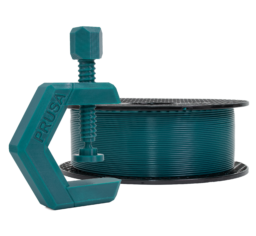

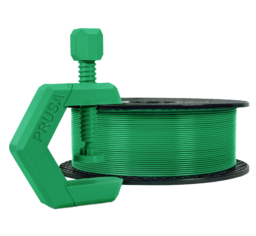

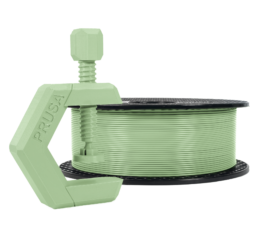

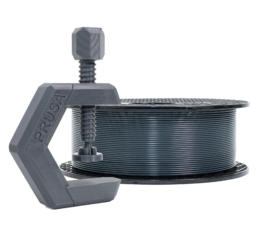

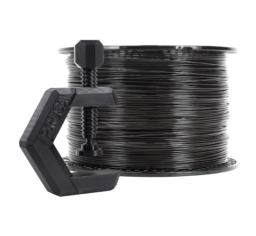

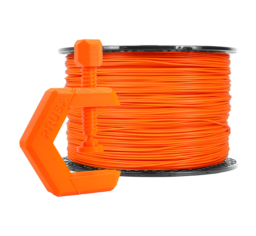

Available colors

Beginners tips & tricks

Print surface preparation

To achieve the best adhesion of the print surface, it is important to keep it clean. Using of isopropyl alcohol is not recommended, because the adhesion may be too strong. You can use the glue stick as a separator however, a better choice is a window cleaner.

Pour a small amount of window cleaner on an unscented paper towel and wipe the print surface. The bed should be cleaned when it’s cold for the best results. If it is cleaned when already preheated for PETG, keep in mind that the cleaner will evaporate before it can clean anything. Alternatively, you can clean the bed with warm water and a few drops of dish soap on a paper towel.

Sanding

When post-processing PETG, it’s possible to use both dry and wet sanding.

Cooling

When printing with PETG, you must consider using a cooling fan. The rapid cooling helps to keep print detailed with no stringing and blobs. If you need the strongest possible print, print with no fan. The higher filament temperature will aid extra strong layer adhesion. We recommend printing the first few layers without the cooling fan to prevent warping and half fan power on after that.

Number of perimeters & strength

If you’re in need of a durable part, increase the number of perimeters rather than increasing the infill percentage as the majority of a 3D print strength comes from its outer shell.