Prusament PETG V0

PETG V0 the one-in-the-world UL-certified self-extinguishing PETG filament. It is especially suitable for housings and insulating parts in electronics, due to its self-extinguishing properties.

Characteristics

Pros

- The one-in-the world UL-certified self-extinguishing filament

- Perfect for plastic parts in electronic appliances

- High temperature resistance

- Easy to print

- Low shrinking and warping

- Strength and Durability

- Not brittle

- Simple to sand

- Mostly odorless while printing

- Glossy and smooth surface finish

Cons

- Hygroscopic material - needs drying before every use

- Not suitable for tiny parts

- Possibility of stringing

- Poor bridging characteristics

- Strong adhesion to the bed - be careful when you’re removing the print

- Cannot be acetone smoothed like ABS

- Supports are harder to remove

- Prone to scratches (more than PLA)

- Slightly worse mechanical properties than regular PETG

Application

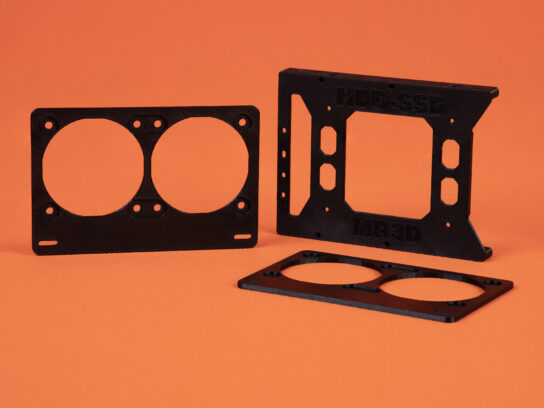

Housings for electronic parts

PETG V0 is especially useful for hobby use, where various electronic installations might cause fire hazard.

Various insulation parts

PETG V0 has insulation properties similar to regular PETG. With UL certification it might help large companies with making rapid prototypes with everything legally sorted out.

Details

- Printing difficulty

- Easy to medium

- Temperature resistance

- 68 °C

- Moisture absorbtion

- High

- Toughness

- Moderate

- Susceptibility to warping

- Low

- Odor

- No odor

- Post processing

- Average

- Solubility

- No

- Elasticity

- Low

- Print speed

- Fast

- Details

- 0.15 mm and more

- Abrasivity

- None

- Hard to break

- Yes

PETG V0 is the one-in-the-world UL-certified self-extinguishing PETG filament. Similarly to the regular Prusament PETG, it is a tough material with good thermal resistance. Its use is universal but especially suitable for housings and insulating parts in electronics, due to its self-extinguishing properties. PETG V0 has almost no warping, so printing large objects isn’t a problem.

We recommend using the Prusament PETG V0 especially for hobby use, where homemade electronic appliances may cause a potential fire hazard. The second large sector welcoming the UL-certified self-extinguishing filament are various large companies that need their products as safe as possible with everything with proper certification.

Self-extinguishing vs. fire-resistant

The self-extinguishing material has usually mechanisms that slow down and eventually stop the flame after it starts burning in the first place. When our Prusament PETG V0 starts burning, it creates a carbonized crust on the surface that prevents the oxygen from getting in and fueling the flame and eventually extinguishes the fire. On the other hand, fire-resistant materials are hard to set on fire in the first place.

The UL certification meaning

In short: the fact that we obtained the UL certification for our filament is a big achievement and a testament to the skills of our Prusament team. The UL is a global safety company that tests various products (materials and mostly electrical equipment) for different levels of safety certifications that are useful in both practical and legal implementations. Almost any product manufacturer can ask them to test their product. The UL company serves as an independent element that guarantees unbiased results for every tested product. Their staff selects the proper testing method (ASTM, IEC, ISO, or other) and accordingly asks the product manufacturer to provide a complete set of test objects. Then, they run the tests in their laboratories and finally provide the certificate of compliance that serves worldwide as legal proof for the product.

We asked the UL to test the flammability of the self-extinguishing PETG marked as Prusament PETG V0. The test method was made according to the IEC 60695-11-10 standard and resulted in a class UL94 V0 (for both our colors). Here’s the Blue Card that serves as a certificate issued by the UL company.

Download Safety Data Sheet (PDF)

Printer requirements

| Bed | Temperature: 80 ± 10 °C Heated Bed Recommended Enclosure not required |

|---|---|

| Print Surface | PEI Glass plate Painter’s tape Glue stick |

| Extruder | Temperature: 230 ± 10 °C No special hot-end required |

| Cooling | Part Cooling Fan Required Fan Speed: 50% |

Beginners tips & tricks

Print surface preparation

To achieve the best adhesion of the print surface, it is important to keep it clean. However, if you’re using smooth PEI print sheet, using isopropyl alcohol is not recommended, because the adhesion may be too strong. You can use the glue stick as a separator to prevent any damage to your print sheet.

The best way is to use a textured or satin print sheet cleaned with isopropyl alcohol: Pour a small amount of isopropyl alcohol on an unscented paper towel and wipe the print surface. The bed should be cleaned when it’s cold for the best results. If it is cleaned when already preheated for PETG, keep in mind that the cleaner will evaporate before it can clean anything. Alternatively, you can clean the bed with warm water and a few drops of dish soap on a paper towel.

Sanding

When post-processing PETG V0, it’s possible to use both dry and wet sanding.

Cooling

When printing with PETG V0, you must consider using a cooling fan. The rapid cooling helps to keep the print detailed with no stringing and blobs. If you need the strongest possible print, print with no fan. The higher filament temperature will aid extra strong layer adhesion. We recommend printing the first few layers without the cooling fan to prevent warping and half fan power on after that.

Drying filament

Prusament PETG V0 needs to be kept as dry as possible as it’s more hygroscopic, compared to regular PETG. If you can’t keep the filament dry, we suggest drying it before use for 6 hours at 55 °C.

Number of perimeters & strength

If you’re in need of a durable part, increase the number of perimeters rather than increasing the infill percentage as the majority of a 3D print strength comes from its outer shell.