Prusament PC Blend Carbon Fiber

Prusament PC Blend Carbon Fiber (PCCF) is a PC Blend filled with carbon fibers to improve its strength, toughness and temperature resistance. Unlike the unmodified PC Blend, PCCF comes with great dimensional stability, good resistance to UV light and common chemicals, better tensile strength and toughness, but most importantly with high-temperature resistance. It’s optimal for printing technical components requiring great strength and high temperature tolerance.

Characteristics

Pros

- Great mechanical properties (tenacity and toughness)

- Excellent temperature resistance (114 °C)

- Possibility of annealing (improving resistance up to 130 °C)

- Dimensional stability – easy printing, possible to print large models

- High wear resistance

- Good UV stability and resistance to common chemicals

- Beautiful, professional-looking matte finish

- Lighter than unmodified Prusament PC Blend

- Enclosure not needed

- No need for drying prior to printing

- Using recycled carbon fibers from the manufacturing process

Cons

- Hardened steel nozzle needed (abrasive material)

- Breakable filament (unlike Prusament PC Blend)

- Higher price

- Lower thickness precision (0.04 mm) caused by carbon fibers inside

Application

Mechanically stressed parts

Because of its toughness and durability, the PC Blend Carbon Fiber is optimal for mechanically stressed parts.

High temperature resistant parts

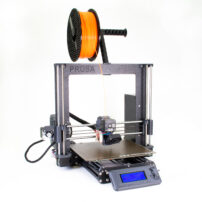

Thanks to the high-temperature resistance up to 114 °C (up to 130 °C resistance using the annealing option), PC Blend Carbon Fiber is a great choice for heat-stressed parts like a fan-shroud on a 3D printer.

Details

- Printing difficulty

- Easy

- Toughness

- Medium

- Odor

- Low

- Solubility

- No

- Print speed

- Fast

- Abrasivity

- High

- Temperature resistance

- 114 °C

- Susceptibility to warping

- Low

- Post-processing

- Easy (easy dry and wet sanding)

- Elasticity

- Low

- Hard to break

- Yes

- Hard to break the filament

- No

Prusament PC Blend Carbon Fiber comes with great mechanical properties, similar to the unmodified PC Blend. But thanks to the carbon fibers added into the filament, it has better heat resistance and dimensional stability. This material is optimal for printing both large and extremely resistant models suitable for engineering applications etc. The possibility of printing large models without using an enclosure is a great advantage when compared to pure PC Blend. Printing with Prusament PC Blend Carbon Fiber requires a hardened steel nozzle. Due to a combination of multiple factors, it is recommended for slightly more experienced users.

Download Safety Data Sheet (PDF)

Printer requirements

| Bed | Temperature: 110 ± 10 °C Heated Bed is necessary Enclosure not needed |

|---|---|

| Print Surface | Smooth PEI sheet with separating agent (paper glue stick KORES) or clean Satin and Powder-coated TXT sheet |

| Extruder | Temperature: 285 ± 10 °C A hardened steel nozzle is needed |

| Cooling | Not recommended |

Available colors

Beginners tips & tricks

Print surface preparation

Powder-coated or satin TXT sheet provides good adhesion. Clean it with IPA (available in drugstores, for example) which works great not only with PCCF but with other materials too.

Pour a small amount of IPA on a paper towel and use it for cleaning the surface. To achieve the best results, clean the surface while it’s cold. Keep in mind that higher temperatures will evaporate the alcohol before cleaning the surface. Also, don’t forget that the heatbed preheated for printing with PCCF has a high temperature (110 °C) and may burn you if you touch it! Another possibility is cleaning the surface with warm water and a few drops of dish cleaner on a paper towel. You can also use denatured alcohol.

We don’t recommend printing with PCCF on a smooth PEI sheet. This material adheres greatly to the PEI surface and may cause damage to it. This type of damage is not covered by the warranty. If you need to print on a smooth surface, spread a thin layer of paper glue stick on it.

Annealing

As we mentioned above, Prusament PC Blend Carbon Fiber has excellent high-temperature resistance. With 114 °C right after printing, it overcomes all other Prusaments. Even better temperature resistance can be achieved with annealing. If executed properly, it can raise the temperature resistance to 130 °C! Plus, thanks to carbon fiber fill, its shrinkage is less than 1%. The whole process is quite easy:

- Print your model with PCCF PrusaSlicer profile

- Preheat the oven to 140 °C

- Put the model inside the oven for 120 minutes

- Pull the model out and let it cool down to room temperature