Prusament PC Blend

PC Blend is perfect for stronger, more durable 3D prints. It is an excellent choice for printing mechanically stressed parts. Compared to other materials, PC Blend has high-temperature resistance.

- For advanced users

- High temperature resistance

- Impact-resistant

- Strength & Rigid

- All details

Characteristics

Pros

- High temperature resistance up to 113 °C

- Excellent mechanical resistance - very strong and rigid material

- Impact-resistant

- Tough and flexible even at low temperatures

- Very good dimensional stability

- Good resistance to creep (cold flow) under mechanical stress

- Does not contain styrene

- Good adhesion to the print sheet

- Improved printing properties compared to conventional polycarbonates - less warping during printing, cracks in layers are very rare

- Does not need to be dried before printing (it is very little hygroscopic)

- Good electrical insulating properties

Cons

- Prone to warping when printing large models

- Requires high temperatures on the nozzle and heatbed

- Higher price

- Produces a noticeable odor during printing

- Requires a separating agent (e.g. a glue stick layer on the print sheet)

Application

Mechanical stressed parts

Because of the strong, tough and rigid material properties, mechanical stressed parts are the most typical usage of PC Blend.

High temperature resistant parts

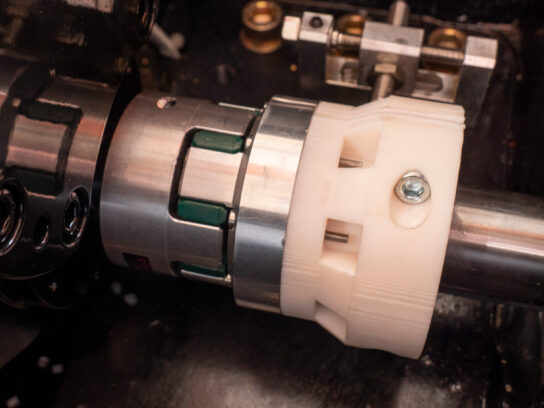

Thanks to the high-temperature resistance up to 113 °C, PC Blend is a great choice for heat-stressed parts like fan-shroud on a 3D printer.

Details

- Printing difficulty

- High

- Temperature resistance

- 113 °C

- Toughness

- High

- Susceptibility to warping

- High

- Odor

- Noticeable

- Post processing

- Easy

- Simple to sand (wet and dry)

- Solubility

- No

- Elasticity

- Medium

- Print speed

- Fast

- Abrasivity

- None

- Hard to break

- Yes

Besides the well-known PLA, PETG and ASA, we now also offer advanced material PC Blend (PolyCarbonate). This material is perfect for stronger, more durable 3D prints. If you are new to 3D printing, you should definitely stick to PLA. PC Blend is recommended for experienced 3D printer owners looking for tough, durable material for production of prototypes and functional parts, thermally and mechanically stressed components.

Download Safety Data Sheet (PDF)

Printer requirements

| Bed | Temperature: 110 ± 10 °C Heated Bed is necessary Skirt or Enclosure Recommended |

|---|---|

| Print Surface | PEI sheet or Powder-coated sheet with separating agent (paper glue stick KORES) |

| Extruder | Temperature: 275 ± 10 °C No special hot-end required |

| Cooling | Part Cooling Fan Required Fan Speed: 20% |

Beginners tips & tricks

Print surface preparation

Prusament PC Blend can be printed on both smooth and textured print sheets. However, it’s required to spread a separating agent on the sheet before you start printing, otherwise the adhesion of the print may be too strong. The easiest way to prepare your print sheet is to apply a thin layer of paper glue onto the sheet. Failing to add a separating layer may lead to the damage to your print sheet! While our documentation states that it’s not necessary to apply glue onto the powder-coated textured print sheet, the PC Blend is an exception. Do not use the glue when printing with other materials (PLA, PETG, ASA, Flex and others)!

How to reduce model deformation during the printing

- Increase the temperature of the heatbed

- Add a brim (width at least 4 mm)

- Add a circular skirt around the model (as high as the model)

- Reduce the number of perimeters and reduce the amount of infill

- Place the model in the center of the pad

- Print smaller objects

- Place the printer in a temperature-stable environment (no cold drafts / draught etc.)

- Avoid printing in a cold environment

- Place the printer into an enclosure