Prusament PA11 Carbon Fiber Black: filamento con eccellente resistenza chimica e al calore

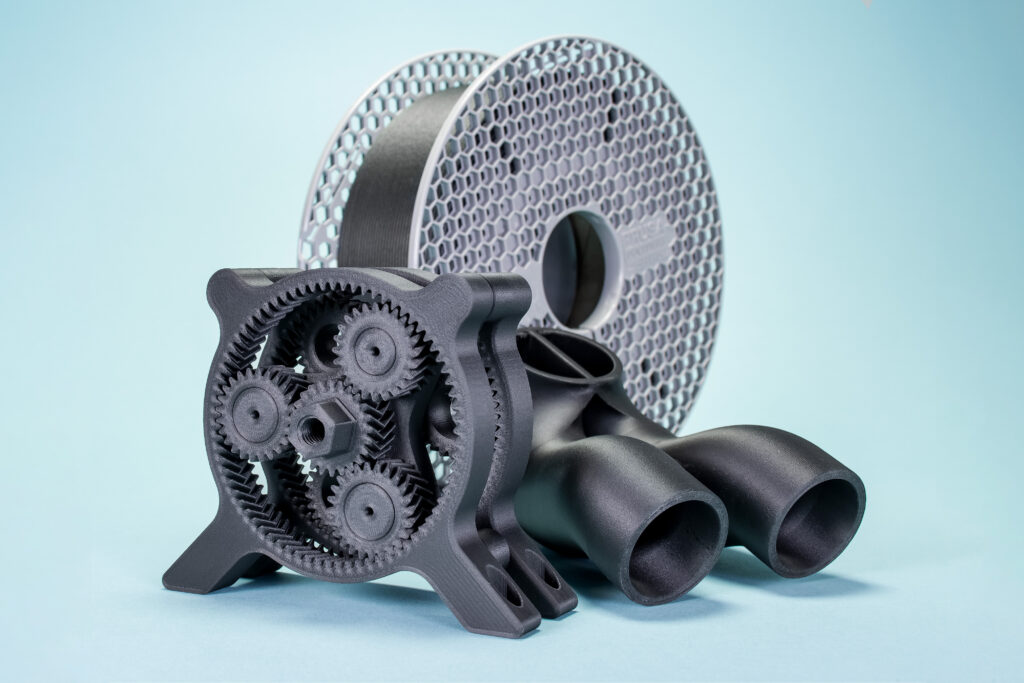

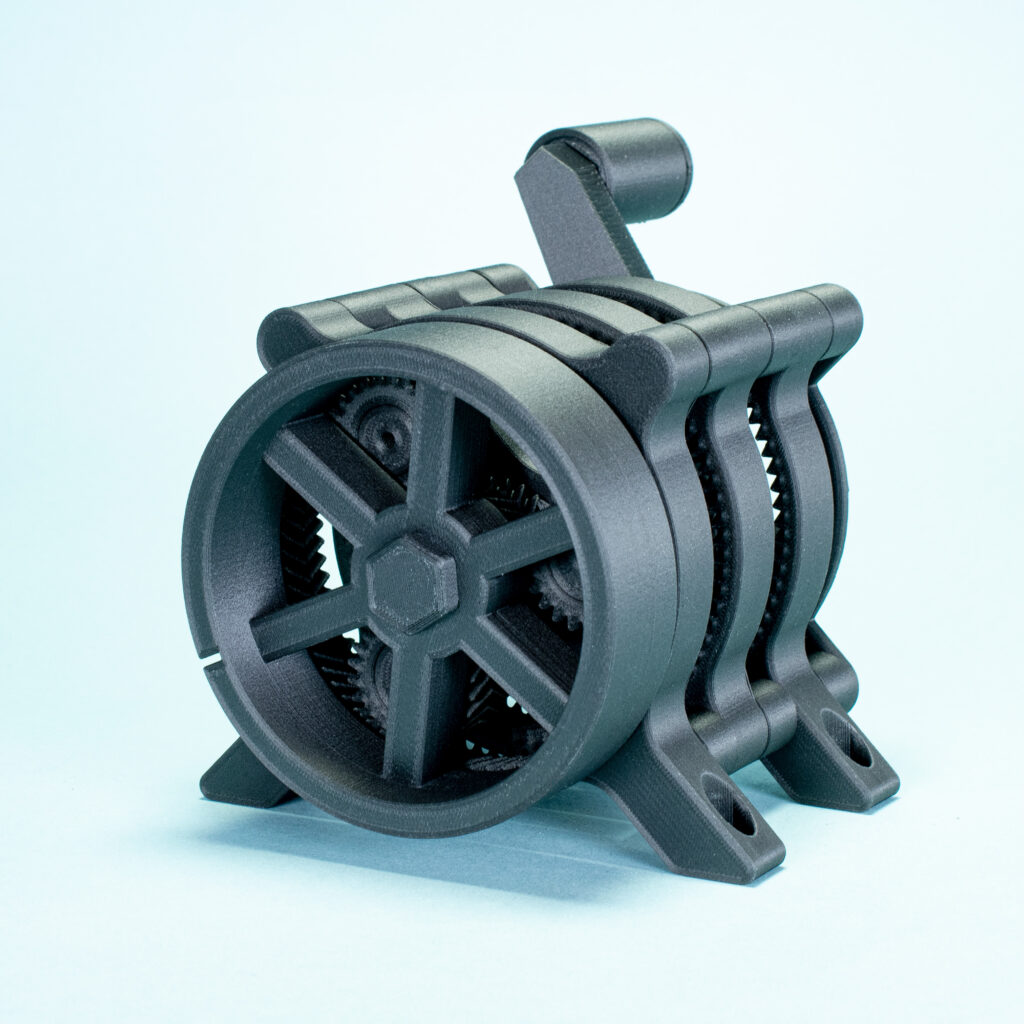

Prusament PA11 Carbon Fiber Black is a Polyamide 11 filled with (recycled) carbon fibers to improve its strength and minimize warping. This material also has a great temperature resistance (up to 190 °C) and its mechanical properties are similar to our Prusament PC Blend Carbon Fiber – due to the impact strength and tensile characteristics, this material is especially suitable for the production of mechanical parts, such as gears and other models where durability is key.

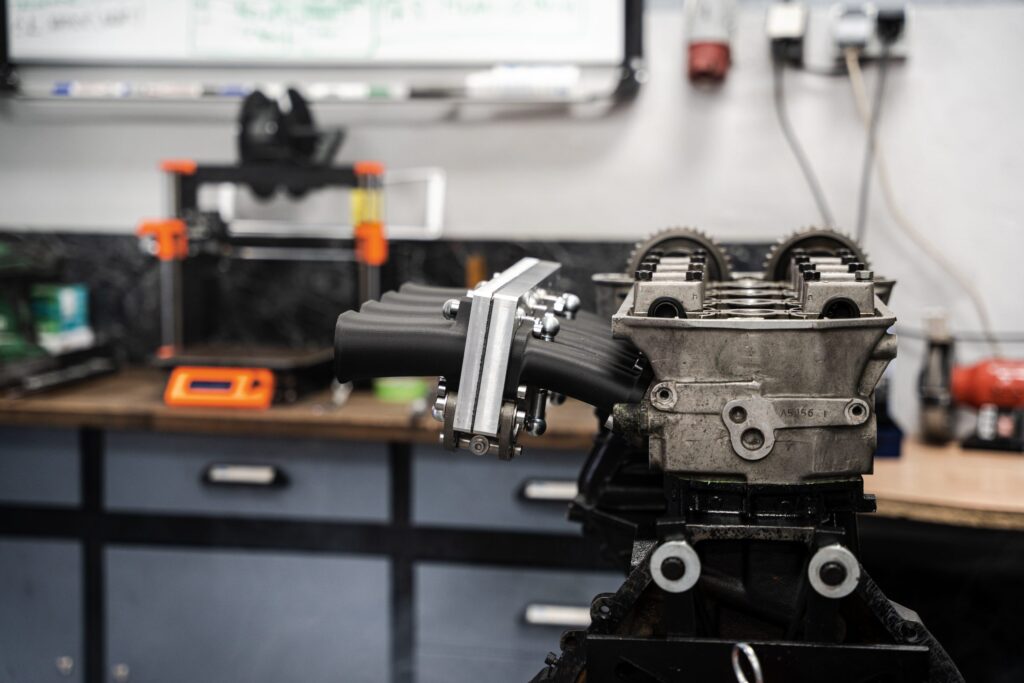

Advanced materials such as the Prusament PC Blend Carbon Fiber greatly expand the possibilities of 3D printing and this is why we’re bringing another new material to the market: Prusament PA11 Carbon Fiber Black, a material perfectly suited for use in the automotive industry, but also great for printing durable mechanical parts at home – components for drones and other RC models, gears and other technical parts.

What is PA11?

Polyamides are a group of polymeric materials produced since the 1930s when DuPont developed polyamide 6.6 known by its trade name Nylon. This name has since become widespread and is often incorrectly applied to other types of polyamides. They are referred to by numbers that represent the number of carbon atoms of the parent compounds – e.g. PA6, PA6.10, PA12, etc.

The PA11 we use is a type of polyamide used primarily for SLS technology. This is a rather unexplored area in the field of FFF 3D printing. We have experimented quite a lot in this field and finally achieved more than a good result. Why did we choose PA11? Commonly used PA6 and PA12 polyamides have a number of disadvantages: PA6 is extremely hygroscopic, making it extremely difficult to print with it even 1 day after unpacking. In some cases, PA6 can get absorb too much moisture even during long printing runs. PA12 isn’t as hygroscopic, but it warps extremely and has very poor adhesion to a standard PEI print sheet. PA11 is a good middle ground – it’s less hygroscopic and offers better adhesion to the PEI print sheet (for small and medium-sized models).

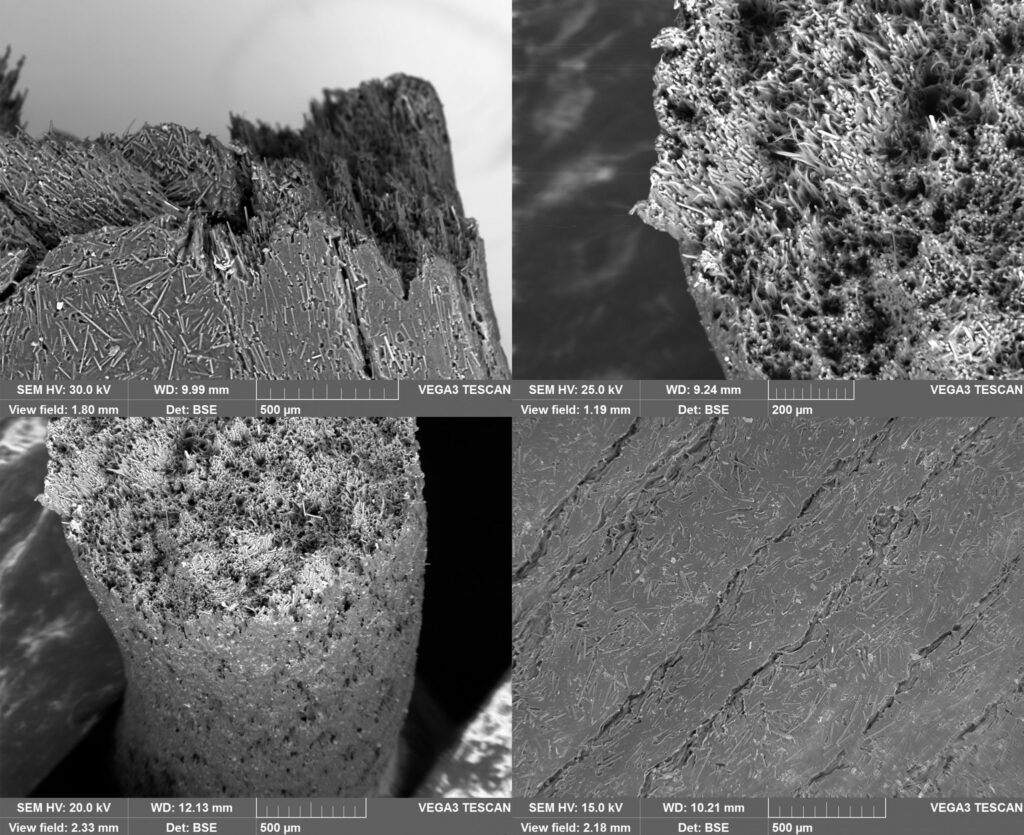

Thanks to added carbon fiber, Prusament PA11 Carbon Fiber is virtually non-warping. Compared to pure polyamide, it has slightly weaker interlayer adhesion, roughly comparable to our Prusament PC Blend Carbon Fiber – still a very good result.

Basic Mechanical and Chemical Properties

Polyamide PA11 is a material made from castor oil, the carbon fibers added to this filament are recycled, as with Prusament PC Blend Carbon Fiber. Probably the biggest advantage of this material is its high-temperature resistance, up to 190 °C depending on the load. This makes it perfectly suitable for printing special parts, such as parts of machines that emit heat (motors, etc.).

The second major advantage of PA11 (and polyamides in general) is its excellent chemical resistance to a range of solvents. PA11 has good resistance to bases (e.g. NaOH), alcohols (Methanol, Ethanol), toluene, acetone, motor oil, petrol, diesel, etc.

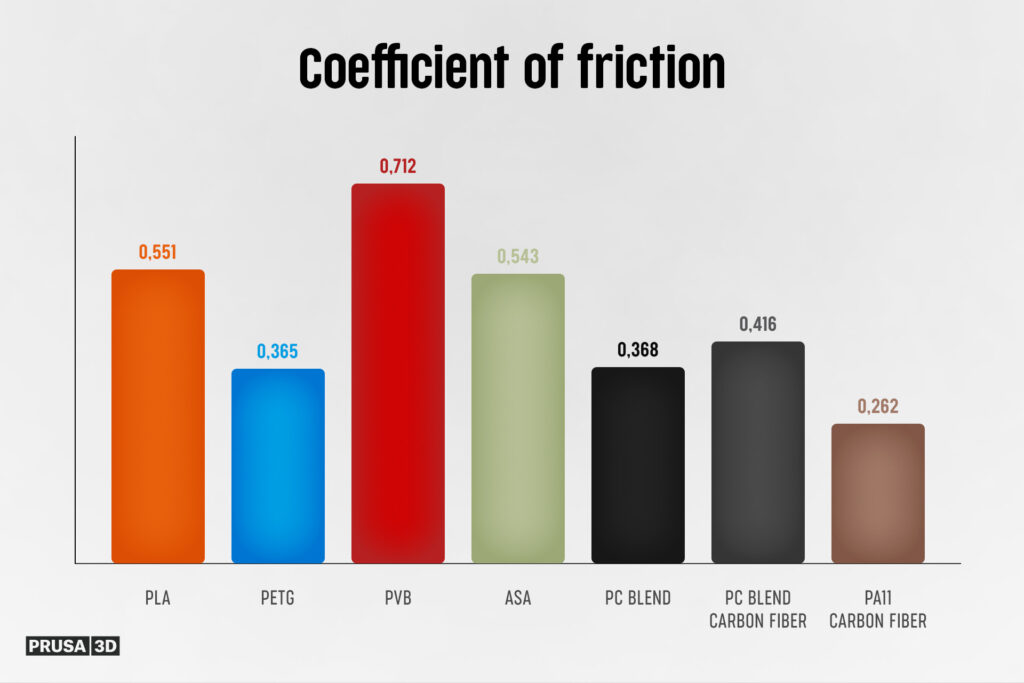

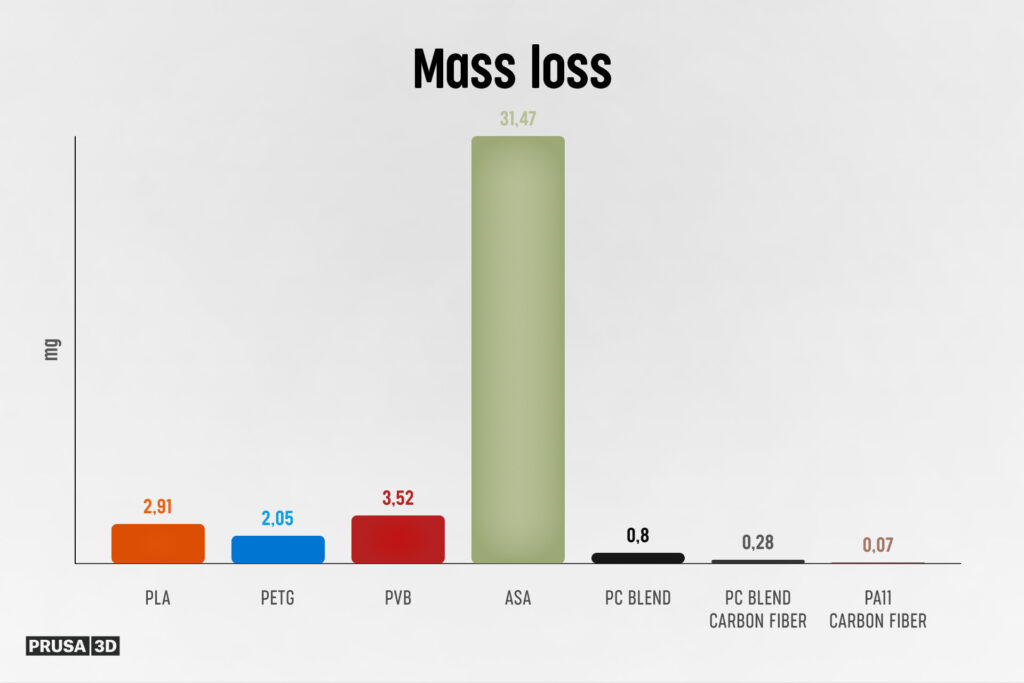

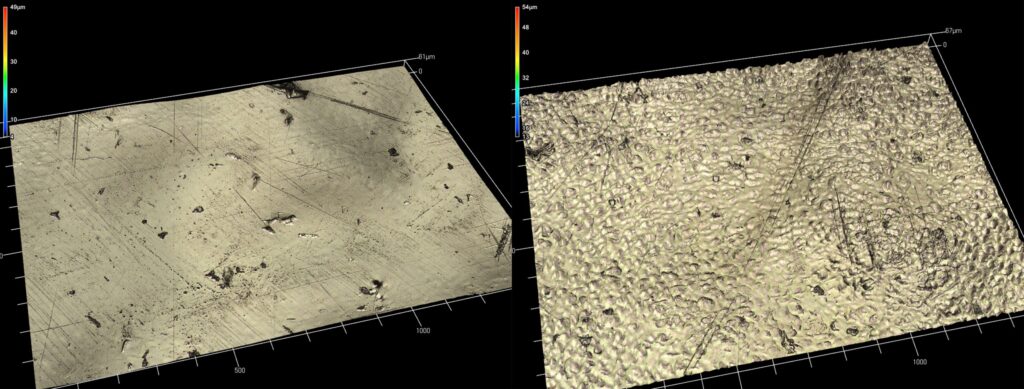

Prusament PA11 Carbon Fiber has good friction and abrasion resistance. This makes it suitable for printing gears and other moving parts. As for other mechanical properties (impact strength, tensile characteristics), these are similar to those of Prusament PC Blend Carbon Fiber. For a better idea, we recommend looking at our material table.

PA11, like other polyamides, is a hygroscopic material (absorbs air moisture). If the absorbed humidity reaches high levels, the print quality will deteriorate. Deterioration occurs between a few days to a month. If you are not sure how long it has been since you opened the sealed bag or if you haven’t been printing for a long time, we recommend drying the filament at 90 °C for 4-6 hours before printing. Absorbing moisture may sometimes be noticeable through removing supports. If the filament is dry, support removal should be easy.

Advantages of printing on a special printing sheet

Together with Prusament PA11 Carbon Fiber Black, we are also releasing a brand new printing sheet designed specifically for printing polyamides. The reason for this is the low adhesion of PA11 to our classic PEI printing sheets. Up until now, we have recommended printing polyamides on textured or satin print sheets with a layer of adhesive (glue stick), but this has not proven to be a very suitable option. Sure, smaller models with sparse infill can be printed on PEI sheets coated with stick glue but for reliable printing of technical models, you need something better. Prusament PA11 Carbon Fiber in particular can easily peel and warp when printed on conventional sheets, despite being filled with carbon fiber. That’s why we have developed a new surface layer of a special material that provides significantly better adhesion for polyamide printing materials.

Our new PA Nylon print sheet comes with a matt texture similar to the satin print sheet. Besides polyamides, it is also compatible with PETG, printing with other materials is not recommended due to a weak adhesion. Even polyamides themselves differ in their composition and may come with various adhesion properties. Many polyamides, especially clean (without carbon fibers for example), have a strong warping tendency. That’s why some materials may require using the brim function even if they stick to the surface nicely. So far, we cannot say if any of the untested polyamides have strong or weak adhesion – that’s why we recommend printing only the polyamides mentioned in our material table. These filaments work just fine with our special PA Nylon print sheets with selected printing temperatures.

For easy print removal and a long sheet lifespan, you need to only wash it with water before every use and set the first layer height. We strongly recommend NOT washing the sheet with Acetone, IPA (isopropyl alcohol) and other alcohol-based chemicals (including window cleaner, 3DLAC, etc.). Using IPA (and other chemicals) makes the surface matt and changes the surface structure and adhesion. This leads to a shorter lifespan and a much higher risk of damaging the sheet. If you have visible grease stains (fingerprints for example), you can clean the sheet with water and dish soap. We recommend washing the sheet with dish soap before turning it on the other side.

Print settings and other printer equipment

In addition to a special print sheet, printing with a hardened nozzle is required due to the highly abrasive properties of carbon fiber. We suggest using the Nozzle X for the best results.

Consigliamo di stampare questo materiale con una stampante in un involucro o posizionando la stampante in una stanza ben ventilata (consultare la scheda di sicurezza del materiale). La stampa di poliammide emana un odore relativamente forte nell’aria ed emette particelle potenzialmente nocive (PUF – particelle ultrafini). La nostra Original Prusa Enclosure è l’opzione ideale. Non solo si ridurrà l’odore, ma la temperatura ambiente più elevata migliora l’adesione tra i layer stampati. Una volta terminata la stampa all’interno dell’involucro, aprire prima la finestra e poi le porte dell’involucro per un rapido ricambio dell’aria.

A causa delle elevate temperature di stampa, si sconsiglia l’uso della stampante Original Prusa MINI+ – la Original Prusa MK3S+ è la soluzione migliore per la stampa con Prusament PA11 Carbon Fiber Black e anche la XL supporterà questo materiale.

Suggerimento: devete aggiungere il profilo di stampa Prusament PA11 Carbon Fiber a PrusaSlicer? Accertatevi di utilizzare PrusaSlicer 2.4.2 o successivo. Andare su Configurazione – Configurazione Guidata – Filamenti – NYLON – Prusa Polymers – mettere la spunta su Prusament PA11 Carbon Fiber e premere Completa. Adesso il profilo PA11 sarà disponibile nell’elenco dei materiali.

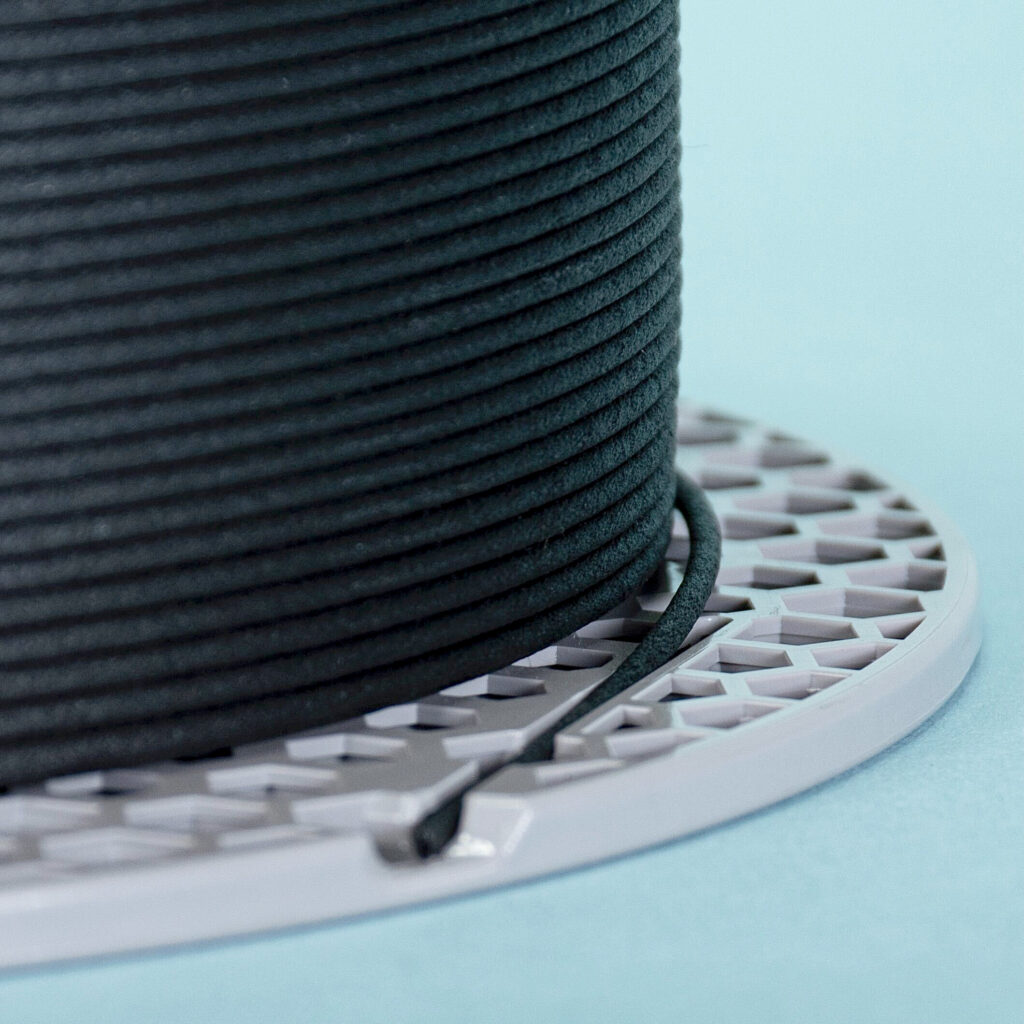

Colore, aspetto e prezzo

Il filamento Prusament PA11 Carbon Fiber Black è nuovamente disponibile in colore nero, per via del contenuto di fibra di carbonio all’interno del filamento. Se vi chiedete perché abbiamo usato colori diversi per i lati della bobina, questi sono grigi per distinguere le bobine incollate da quelle piegate. Quando si essicca il filamento (90°C), i lati della bobina si espandono termicamente e, una volta raffreddati, la bobina può smantellarsi. Per questo motivo, abbiamo dovuto incollare le parti in carta e plastica. È comunque possibile riciclare la carta e la plastica allo stesso modo delle bobine normali, basta esercitare un po’ più di forza per smontare la bobina.