How it’s made

Current market couldn’t satisfy our need for high-quality filaments, so we decided to make our own – with premium-grade materials and strict quality control.

DEHUMIDIFYING THE PLASTIC PELLETS

At the start, the polymer used for filament manufacturing is in the form of colorless plastic pellets. In this state, it’s prone to absorbing the moisture from the air. The plastic pellets are sucked into a dryer. Using a dry air aggregate with a series of dust filters, we dehumidify the pellets before sending it to the extrusion line.

COLOR MEASURING AND AUTOMATIC COLOR DOSAGE

The final color of the filament is determined by the addition of pigment to the clear plastic granulate. During the manufacturing process, the color is being constantly measured and the pigment dosage is adjusted in real time accordingly to the CIELAB ΔE metric. Should the color get out of acceptable tolerance anytime during the manufacturing, the spool is immediately discarded.

EXTRUSION

The granulate is melted in a sequence of heated zones with gradually increasing temperature. A screw pushes the molten plastic forward until it reaches the die head. After that, the extruded plastic immediately enters the cooling baths.

Cooling

Extruded filament travels through a series of cooling baths. These baths contain specially treated soft water with antibacterial and rust preventing solutions.

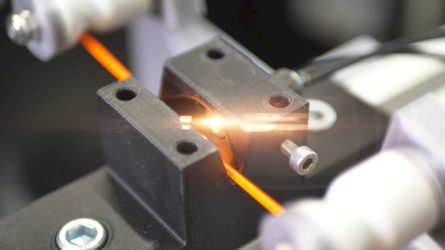

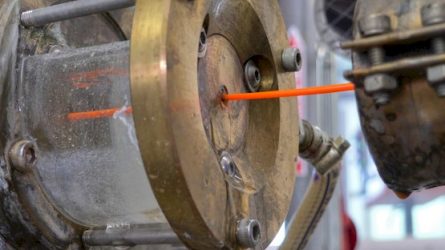

2-AXIS LASER DIAMETER MEASURING

Accurate filament diameter is one of the most important characteristics of Prusament. It’s being measured 4700× per second in two axes perpendicular to each other. These measurements are saved in our database and can be viewed online. Unlike the industry standard of +-0.05 mm, our tolerance limit is set to +-0.02 mm for the vast majority of materials (±0.03 mm for blended materials).