Prusament Resin Flex

Prusament Resin Flex80 is a high-quality rubber-like resin with a hardness of around 80 Shore A. It is designed to print objects with a soft, yet durable finish, providing the perfect balance between flexibility and strength. The flexibility of printed objects can be compared to a car tire, leather, tendons, or a rubber shoe sole.

Caratéristiques

Avantages

- Print reliability

- Short exposure time

- Great print detail

- Soft, rubber-like and durable

- Hardness similar to car tire or rubber shoe sole

Désavantages

- Non-recyclable material

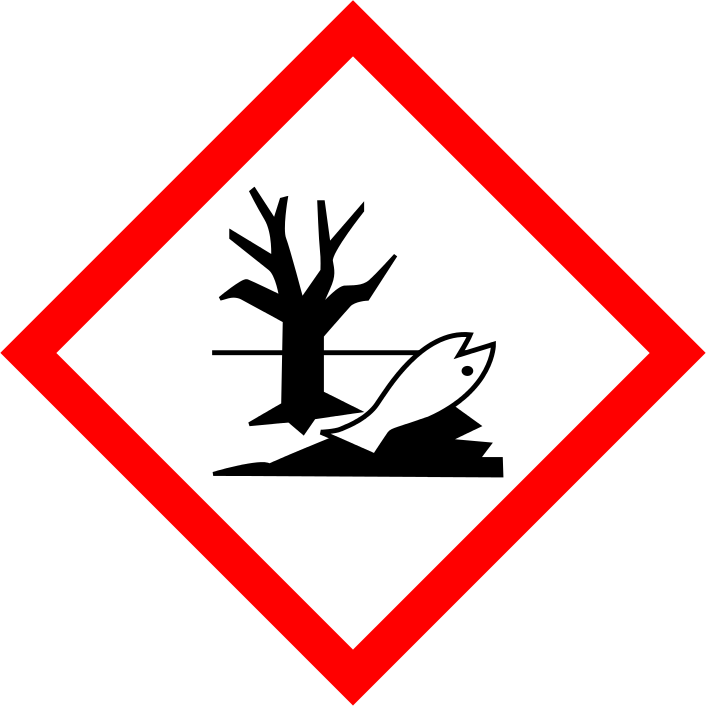

- Uncured resin may pose a health risk

Utilisation

Model & hobby

Thanks to the high level of detail, this material is suitable for printing durable figures, RC car tires and other intricate objects that need a soft finish and rubber-like properties.

Rapid prototyping

Short exposure time and the perfect level of detail make the MSLA technology suitable for small and detailed prototypes that can’t be done with FFF/FDM printers. Plus, overall MSLA printing time is shorter than with FFF/FDM.

Education models

Prusament Flex80 is perfect for printing organic-like structures and/or medical models with great durability and good flexibility. This makes it ideal for printing, e.g., models of human organs.

Informations

Prusament Resin Flex80 is easy to use resin and provides detailed prints. It is capable of fast printing of parts with intricate features while ensuring that they remain flexible, which makes it a perfect choice for rapid prototyping, functional parts, durable figures, RC car parts, organic structures, medical models, and many other objects. Compared to most other flexible resins on the market, our Prusament Resin Flex80 has a noticeably lower odor and viscosity allowing the finished models to be easily washed in isopropyl alcohol without special washing and post-curing procedures.

Prusament Resin Flex80 is currently offered in two colors: Transparent Clear and Black. It’s a great option for printing RC car tires, durable rubber-like figures, prototypes, medical models, functional parts and much more. Please follow the safety instructions for working with resins; wear gloves when handling uncured resin.

Printing Setup

Use built-in PrusaSlicer profiles for best results.

Transparent Clear

| Original Prusa SL1 | 15 seconds per layer at 0.05mm layer height |

| Original Prusa SL1S SPEED | 5 seconds per layer at 0.05mm layer height; SLOW profile |

Black

| Original Prusa SL1 | 10 seconds per layer at 0.05mm layer height |

| Original Prusa SL1S SPEED | 3 seconds per layer at 0.05mm layer height; SLOW profile |

Troubleshooting tips:

Use supports with higher density (200 %) and head penetration (0.6 mm)

Use a High-Viscosity profile in case of printing issues

Download Safety Data Sheet Black (PDF)

Download Safety Data Sheet Transparent Clear (PDF)

Download Safety Data Sheet White (PDF)

Couleurs disponibles

Trucs et astuces de débutant

Before you start using Prusament Resin, don’t forget to read the material safety data sheet (MSDS) uploaded at prusament.com. Here, we sum up only a few tips that might make your life with resin a little easier.

- Always remember that despite our hardest efforts, all liquid resins still might pose a health risk. Use protective equipment, especially gloves, every time you work with resin. Prevent contact with skin, eyes, and mouth.

- Accidents happen even to the most experienced users. If resin gets on your printer, table, or anything else, don’t wait and clean it immediately with paper towels and isopropyl alcohol (IPA), before it gets cured by the daylight.

- Strangely enough, there is not much information available about waste disposal and recycling 3D printed products. Let’s sum up how we deal with resin waste: Uncured resin leftovers should be disposed of with other dangerous chemicals at places designated for it. It cannot be recycled and definitely should not end in general waste.

The same rule applies to bottles, paper towels, and models stained with liquid (uncured) resin. However, cured resin (reactoplastic material) is, unlike filaments (thermoplastic material), a non-recyclable material – it belongs in the general waste.